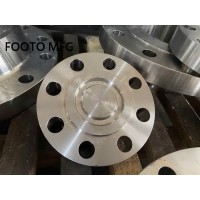

ASME B16.5 ASTM A182 F53 GR2507 Lap Joint Flange CL600 100NB

ASME B16.5 ASTM A182 F53 GR2507 Lap Joint Flange CL600 100NB

| Categories | Duplex Super Duplex Flanges |

|---|---|

| Brand | Footo |

| Model | 4”600LBS LJ S32750 |

| FOB port | Shanghai;Ningbo |

| Terms of Payment | L/C, D/A, D/P, Western Union, MoneyGram, T/T, Paypal |

| Update Time | Apr 4,2025 |

ASME B16.5 ASTM A182 F53 GR2507 Lap Joint Flange

1. Material: 2507 (UNS 32750/F53), etc 2. Size: 4" (DN100) 3. Standard: ASME B16.5, DIN, etc

4. Pressure: 150#, 300#, 600#, etc

ASME B16.5 ASTM A182 F53 GR2507 Lap Joint Flange, CL600, 100NB.

1. Material: 2507 (UNS 32750/F53), etc

4. Pressure: 150#, 300#, 600#, etc

ASME B16.5 ASTM A182 F53 GR2507 Lap Joint Flange, CL600, 100NB.

Chemical Composition Of F53 UNS 32750 GR2507 Super Duplex Stainless Steel

GRADE | C≤ | Mn≤ | Si≤ | S≤ | P≤ | Cr≤ | Ni | Mo | Cu≤ | N |

S32750 (2507) 00Cr25Ni7Mo4N | 0.03 | 1.20 | 0.8 | 0.020 | 0.035 | 24.0/26.0 | 6.0/8.0 | 3.0/5.0 | 0.50 | 0.24/0.32 |

About: ASME B16.5 ASTM A182 F53 GR2507 Lap Joint Flange

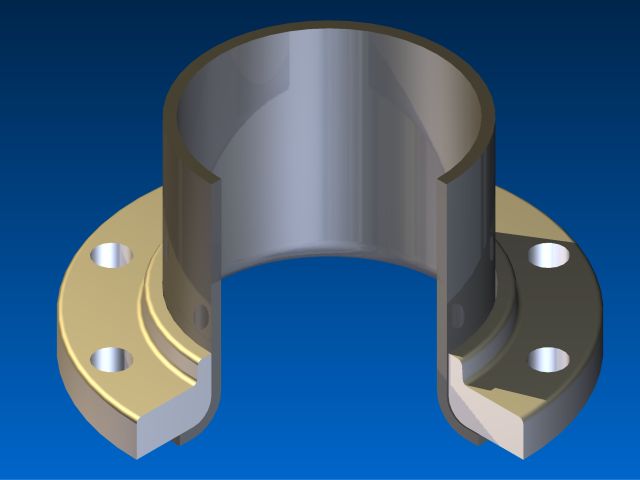

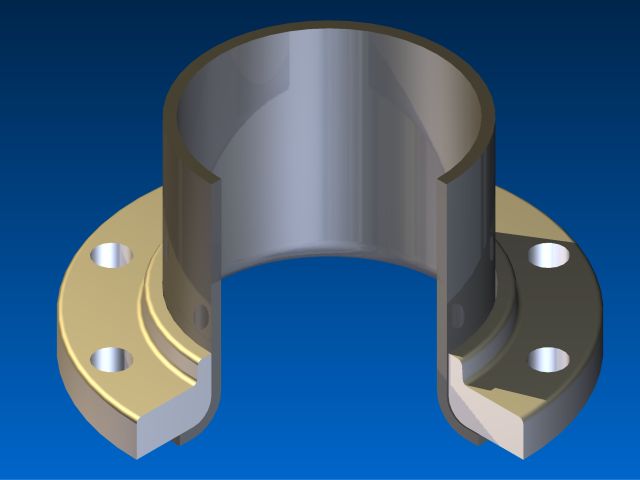

F53 GR2507 Lap Joint Flange (LJ Flanges) or F53 GR2507 Loose flange (F53 GR2507 LF flange) called are used on piping fitted with lapped pipe or with lap joint stub ends the combined initial cost of the two items being approximately one-third higher than that of comparable welding neck flanges. Their pressure-holding ability is little, if any, better than that of slip-on flanges and the fatigue life of the assembly is only one-tenth that of welding neck flanges. The F53 GR2507 lap joint flanges with the stub end assembly are normally used in systems requiring frequent dismantling for inspection and cleaning and where the ability to swivel flanges and to align bolt holes materially eases the erection of large diameter or unusually stiff piping. F53 GR2507 Lap Joint flanges have certain special advantages: Freedom to swivel around the pipe facilitates the lining up of opposing flange bolt holes. Lack of contact with the fluid in the pipe often permits the use of inexpensive carbon steel flanges with corrosion resistant pipe. In systems which erode or corrode quickly, the flanges may be salvaged for re-use.

Slip on Pipe flanges with a hub have published specifications that range from 1/2" thru 24". Sizes above 24" are produced as lap joints to slip on dimensions. Coastal Flange provides F53 GR2507 Lap Joint pipe flanges in all material grades, specifications and sizes.

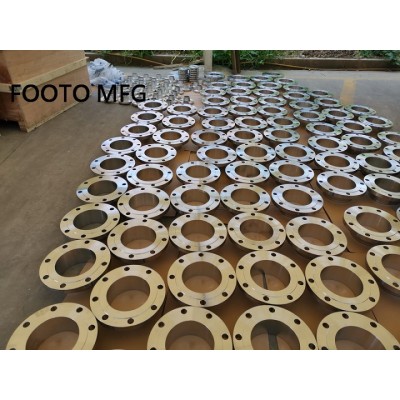

Footo MFG manufactures lap joint pipe flanges in all steel material grades, including Super duplex stainless steel lap joint pipe flanges, stainless steel lap joint pipe flanges and alloy lap joint pipe flanges. Footo MFG also has many different lap joint pipe flanges in stock and ready to ship. Footo MFG can also manufacture custom pipe flanges according to customer specifications.

Materials For Lap Joint Flange

The most common materials used in flanges produced is carbon steel, super duplex stainless steel, duplex stainless steel, stainless steel, cast iron, aluminium, brass, bronze, plastic etc.

In addition, flanges, like fittings and pipes, for specific purposes sometimes internally equipped with layers of materials of a completely different quality as the flanges themselves, which are "lined flanges".

The material of a flange, is basically set during the choice of the pipe, in most cases, a flange is of the same material as the pipe.

F53 Lap Joint Flange Installation

Center the gasket on the flange. This is extremely vital where raised faces are involved. Note: standard ANSI ring gaskets, when cut properly, should center themselves with the bolts in place.

Use a torque wrench and well-lubricated fasteners with hardened flat washers to ensure correct initial loading.

Tighten bolts to compress gasket uniformly. This means going from side to side around the joint, in a star-like crossing pattern.

All bolts should be tightened in one-third increments, according to proper bolting patterns. Retorque 12 to 24 hours after start-up, whenever possible.

All applicable safety standards including lockout/tagout procedure should be observed.

Never use liquid or metallic based anti-stick or lubricating compounds on the gaskets. Premature failure could occur as a result.

APPLICATIONS Of F53 Lap Joint Flange:

1. petrochemical industry

2. Pharmaceutical industry

3. Food industry

4. Aviation and aerospace industry

5. Architectural decoration industry

6. Oil and gas industry

Other Features:

1) Chemical and Physical characteristic: durable, corrosion resistant and high-temperature resistant

2) We also produce flange with special specifications according to customers’ requirements;

Packing

1) Packing Method:

Normal packing: Plastic film or bubble paper wrapped, endings protect by caps,

then into wooden case or load on fumigation plywood pallet.

Custom product: As per your request.

2) Shipping:

By Sea, By Air, By Train or River-and-Sea Coordinated Transport, according to your request.

Where can we find the high quality ASME B16.5 ASTM A182 F53 GR2507 Lap Joint Flange.

You can visit this website: www.cnfooto.com

If any inquiry about products, please feel free to contact us sales@cnfooto.com

About: ASME B16.5 ASTM A182 F53 GR2507 Lap Joint Flange

F53 GR2507 Lap Joint Flange (LJ Flanges) or F53 GR2507 Loose flange (F53 GR2507 LF flange) called are used on piping fitted with lapped pipe or with lap joint stub ends the combined initial cost of the two items being approximately one-third higher than that of comparable welding neck flanges. Their pressure-holding ability is little, if any, better than that of slip-on flanges and the fatigue life of the assembly is only one-tenth that of welding neck flanges. The F53 GR2507 lap joint flanges with the stub end assembly are normally used in systems requiring frequent dismantling for inspection and cleaning and where the ability to swivel flanges and to align bolt holes materially eases the erection of large diameter or unusually stiff piping. F53 GR2507 Lap Joint flanges have certain special advantages: Freedom to swivel around the pipe facilitates the lining up of opposing flange bolt holes. Lack of contact with the fluid in the pipe often permits the use of inexpensive carbon steel flanges with corrosion resistant pipe. In systems which erode or corrode quickly, the flanges may be salvaged for re-use.

Slip on Pipe flanges with a hub have published specifications that range from 1/2" thru 24". Sizes above 24" are produced as lap joints to slip on dimensions. Coastal Flange provides F53 GR2507 Lap Joint pipe flanges in all material grades, specifications and sizes.

Footo MFG manufactures lap joint pipe flanges in all steel material grades, including Super duplex stainless steel lap joint pipe flanges, stainless steel lap joint pipe flanges and alloy lap joint pipe flanges. Footo MFG also has many different lap joint pipe flanges in stock and ready to ship. Footo MFG can also manufacture custom pipe flanges according to customer specifications.

Materials For Lap Joint Flange

The most common materials used in flanges produced is carbon steel, super duplex stainless steel, duplex stainless steel, stainless steel, cast iron, aluminium, brass, bronze, plastic etc.

In addition, flanges, like fittings and pipes, for specific purposes sometimes internally equipped with layers of materials of a completely different quality as the flanges themselves, which are "lined flanges".

The material of a flange, is basically set during the choice of the pipe, in most cases, a flange is of the same material as the pipe.

F53 Lap Joint Flange Installation

Center the gasket on the flange. This is extremely vital where raised faces are involved. Note: standard ANSI ring gaskets, when cut properly, should center themselves with the bolts in place.

Use a torque wrench and well-lubricated fasteners with hardened flat washers to ensure correct initial loading.

Tighten bolts to compress gasket uniformly. This means going from side to side around the joint, in a star-like crossing pattern.

All bolts should be tightened in one-third increments, according to proper bolting patterns. Retorque 12 to 24 hours after start-up, whenever possible.

All applicable safety standards including lockout/tagout procedure should be observed.

Never use liquid or metallic based anti-stick or lubricating compounds on the gaskets. Premature failure could occur as a result.

APPLICATIONS Of F53 Lap Joint Flange:

1. petrochemical industry

2. Pharmaceutical industry

3. Food industry

4. Aviation and aerospace industry

5. Architectural decoration industry

6. Oil and gas industry

Other Features:

1) Chemical and Physical characteristic: durable, corrosion resistant and high-temperature resistant

2) We also produce flange with special specifications according to customers’ requirements;

Packing

1) Packing Method:

Normal packing: Plastic film or bubble paper wrapped, endings protect by caps,

then into wooden case or load on fumigation plywood pallet.

Custom product: As per your request.

2) Shipping:

By Sea, By Air, By Train or River-and-Sea Coordinated Transport, according to your request.

Where can we find the high quality ASME B16.5 ASTM A182 F53 GR2507 Lap Joint Flange.

You can visit this website: www.cnfooto.com

If any inquiry about products, please feel free to contact us sales@cnfooto.com

- Tel

- *Title

- *Content

- KEEP UP TO DATE

- Sign up for our newsletter and follow us on social media

Footo MFG

Footo MFG